Welcome

EazyCNC

jDraft 2.0

PureJavaComm

PIC CDC ACM

Weather

Ten-Buck Furnace

H8S Bootloader

Camera Calibration

Multitouch

Myford VFD

Fun with HC08

bl08

printf II

Java Goes Native

Densitometer

printf

jApp

Igloo

New Furnace

New Furnace

Part II

Linux 101

H8S/gcc

Quickie

Gas Fired Furnace

Down Memory Lane

Exlibris

Wheel Patterns

Glitches

CHIP-8

eDice

Animato

jDraft

JNA Benchmark

Contact Info

New Furnace

Come spring of -04 and I unearthed the

furnace . Last melt of the previous autumn had manifested

some problems,

the burner tended to backfire and it took a long time to get to melt

temperature. A litle investigation revealed that

the furnace was totally clogged up by iron spills. Originally this

furnace had no bottom (in fact it was a plain tube!) but

I had added a bottom to improve insulation. This was probably futile as

far as heat losses are concerned and stupid

as far as spill are concerned, as there was no hole at the bottom and

the bottom was unremovable. How unremovable it was,

I soon found out.

I tried to hammer (gently as you can with a 4 kg sledge) the bottom

out, and the whole thing fell a part!

Come spring of -04 and I unearthed the

furnace . Last melt of the previous autumn had manifested

some problems,

the burner tended to backfire and it took a long time to get to melt

temperature. A litle investigation revealed that

the furnace was totally clogged up by iron spills. Originally this

furnace had no bottom (in fact it was a plain tube!) but

I had added a bottom to improve insulation. This was probably futile as

far as heat losses are concerned and stupid

as far as spill are concerned, as there was no hole at the bottom and

the bottom was unremovable. How unremovable it was,

I soon found out.

I tried to hammer (gently as you can with a 4 kg sledge) the bottom

out, and the whole thing fell a part!

So, I was in for some furnace construction. Since I had the Gingery Building a Gas Fired Crucible Furnace I thought I'd have a go based on that design. A lot of people have have built it and have not reported problems so I figured it would be ok. On paper the desing seems great and has some nice features. The construction is very economical, it is difficult to see how it could be improved in that respect.

Note that this page is not a DIY instruction, if you want to build one to the Gingery design, go and buy the book. It is worth the dime and we should all engourage people like him to write more on the good stuff.

Having said that the brief discription of the furnace is as follows.

The furnace is made of three parts.

This design has several good points to it: safer access to crucible because , small foot print, compact and economical construction, fast pour/recharge action, simple and inherently rather safe desing.

All features you'll appreciate in a backyard foundry.

The fine print: when above I write safe, it does not mean that the design or activity is safe, it simply means that it is safer than many other designs / practices. Make no mistake, this is dangerous activity. You and you alone will be responsible if you pursue these activities. Do your own risk assement and act accordingly.

Because I was

planning on casting some roof braces for our conservatory project I

wanted to build a slightly larger furnace that could accomondate

a larger crucible. So I needed to scale up the Gingery desing. This was

a good way to test drive my 2D-CAD program,

jDraft . On the left you can see the scaled up but basically

'standard' Gingery furnace, as captured from my screen. If you are a

jDraft user you can down load the drawing which includes the

dimensioning from here .

If you are not a jDraft user you need to

download jDraft first by visiting the jDraft home page. But you might

want to read the whole story first.

Because I was

planning on casting some roof braces for our conservatory project I

wanted to build a slightly larger furnace that could accomondate

a larger crucible. So I needed to scale up the Gingery desing. This was

a good way to test drive my 2D-CAD program,

jDraft . On the left you can see the scaled up but basically

'standard' Gingery furnace, as captured from my screen. If you are a

jDraft user you can down load the drawing which includes the

dimensioning from here .

If you are not a jDraft user you need to

download jDraft first by visiting the jDraft home page. But you might

want to read the whole story first.

began the construction by cutting two circular

holes to two pieces of plywood with my rooter. Amazing tool, even if

you missposition the cutter so that you are effectively cutting with

the stemp of the cutter only, it just burns away the wood! Mind you

there is a lot of smoke. I also cut two circular discs to be used as

the inside former supports. Actually, one of

these discs was cut so that it was a ring so that I could get my hand

into the inside of the former.

began the construction by cutting two circular

holes to two pieces of plywood with my rooter. Amazing tool, even if

you missposition the cutter so that you are effectively cutting with

the stemp of the cutter only, it just burns away the wood! Mind you

there is a lot of smoke. I also cut two circular discs to be used as

the inside former supports. Actually, one of

these discs was cut so that it was a ring so that I could get my hand

into the inside of the former.

I actually would have needed more of these but

by doing the base, body and lid of the furnace each in turn I was able

to recycle these parts.

I actually would have needed more of these but

by doing the base, body and lid of the furnace each in turn I was able

to recycle these parts.

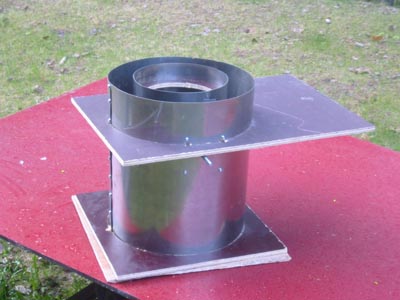

The inside former of the furnace body

is made of 1 mm thick mild steep plate. Two small slots were cut into

the inside discs' outer circumference and the end of the inside former

plate was bent to angle so that the end of the plate would fit into the

slot. Then I rolled the plate around the formers. Mild steel was pretty

easy to form

except that I was not able to form a perfect cylinder even with the

help of some heavy pressure from load tying lines.

Finally the former cylinder was secured with some M4 nuts and bolts and

the ever so versatile duct tape.

The inside former of the furnace body

is made of 1 mm thick mild steep plate. Two small slots were cut into

the inside discs' outer circumference and the end of the inside former

plate was bent to angle so that the end of the plate would fit into the

slot. Then I rolled the plate around the formers. Mild steel was pretty

easy to form

except that I was not able to form a perfect cylinder even with the

help of some heavy pressure from load tying lines.

Finally the former cylinder was secured with some M4 nuts and bolts and

the ever so versatile duct tape.

You can, just about, see the slot in the plywood

ring and the angled plate edge in this picture if you look carefully.

You can, just about, see the slot in the plywood

ring and the angled plate edge in this picture if you look carefully.

The outside former for the furnace body I made

from similar steel plate. It was easier to get a good cylinder with

plywood on the outside. Again the former was secured with M4 nuts

and bolts, this time rather many of them about 50 mm appart, as these

bolts are actually the king pins that hold the furnace body

jacket together and prevent it from slipping out. And the body weights

some 65 kg!

The outside former for the furnace body I made

from similar steel plate. It was easier to get a good cylinder with

plywood on the outside. Again the former was secured with M4 nuts

and bolts, this time rather many of them about 50 mm appart, as these

bolts are actually the king pins that hold the furnace body

jacket together and prevent it from slipping out. And the body weights

some 65 kg!

The two pins that the furnace body rests on are

made of M10 bolts weleded to and re-inforced with some 100 x 100 x 2

mm3 steel plates secured with four M4 nuts and bolts to the furnace

body jacket.

The two pins that the furnace body rests on are

made of M10 bolts weleded to and re-inforced with some 100 x 100 x 2

mm3 steel plates secured with four M4 nuts and bolts to the furnace

body jacket.

Inside view of furnace body jacket/outside

former. BTW all the outside former plates are left in place ie they are

part of the furnace lining jacket. A full metal jacket?

Inside view of furnace body jacket/outside

former. BTW all the outside former plates are left in place ie they are

part of the furnace lining jacket. A full metal jacket?

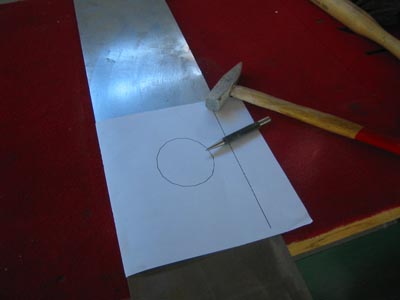

The burner hole in the base part furnace molds

was

a fun excersize in geometric projection with the jDraft. I printed the

ellipsoid shaped profile of the hole onto a paper that I placed

on top of the steel plate and punched through to mark the hole outline.

The burner hole in the base part furnace molds

was

a fun excersize in geometric projection with the jDraft. I printed the

ellipsoid shaped profile of the hole onto a paper that I placed

on top of the steel plate and punched through to mark the hole outline.

Amazingly the Black&Decker recip saw

just crunched away the metal!

Amazingly the Black&Decker recip saw

just crunched away the metal!

Here the base mold is being tryed out.

Here the base mold is being tryed out.

And here the furnace bottom mold is just before

casting the refactory. The four square pieces of plywood were retracted

as I rammed the refactory and the mold filled up.

And here the furnace bottom mold is just before

casting the refactory. The four square pieces of plywood were retracted

as I rammed the refactory and the mold filled up.

The lid mold was done pretty much like the

other, I just bolted a piece of angle iron to function as a hinge and

applied some zinc-coated wires across the lid. These are supposed to

attache the frame band to the refactory and also prevent pieces falling

out in case the lid

cracks. BTW, as I said, the base, body and lid were done each in turn

(so not in the sequence show here) so that I could re-use the plywood

formers, like here underneat you can see the same plywood former that

was used to hold the base and the body formers together.

The lid mold was done pretty much like the

other, I just bolted a piece of angle iron to function as a hinge and

applied some zinc-coated wires across the lid. These are supposed to

attache the frame band to the refactory and also prevent pieces falling

out in case the lid

cracks. BTW, as I said, the base, body and lid were done each in turn

(so not in the sequence show here) so that I could re-use the plywood

formers, like here underneat you can see the same plywood former that

was used to hold the base and the body formers together.

Unlike Gingery I prefer the

commercial variety for my refactory lining. Not because I would not

like to make this myself, I would, but because I feel this is a safety

/ furnace life time issue. An it is not THAT expensive.

Unlike Gingery I prefer the

commercial variety for my refactory lining. Not because I would not

like to make this myself, I would, but because I feel this is a safety

/ furnace life time issue. An it is not THAT expensive.

Mixing the stuff is rather hard work and boring.

I used as litle water as possible, the constituency of the mixture was

like porridge made from oat (but not corn ;-) flakes with too litle

water.

Mixing the stuff is rather hard work and boring.

I used as litle water as possible, the constituency of the mixture was

like porridge made from oat (but not corn ;-) flakes with too litle

water.

I just spooned the mixture

into the mold a plastic-cup-full at a time and rammed it hard with a

stick. Too hard as it turned out.

I just spooned the mixture

into the mold a plastic-cup-full at a time and rammed it hard with a

stick. Too hard as it turned out.

After about an hour the body

was filled to the rim.

After about an hour the body

was filled to the rim.

Compared to the body work the lid was a piece

of cake, a pun-cake? (Sorr abot that)

Compared to the body work the lid was a piece

of cake, a pun-cake? (Sorr abot that)

The base was first filled to the level of the

furnace bottom. The pipe is there, of course, to leave a hole in the

lining for the tangential burner insert. Note that there is a hole in

the bottom to let spilled molten metal to flow out, it is just

difficult to see in this picture as the plug that forms the hole is

covered with white refractory stuff.

The base was first filled to the level of the

furnace bottom. The pipe is there, of course, to leave a hole in the

lining for the tangential burner insert. Note that there is a hole in

the bottom to let spilled molten metal to flow out, it is just

difficult to see in this picture as the plug that forms the hole is

covered with white refractory stuff.

Then the inside former was inserted and and

centered with the afore mentioned pieces of plywood and the rest of the

lining rammed in while the plywood pieces were retrackted.

Then the inside former was inserted and and

centered with the afore mentioned pieces of plywood and the rest of the

lining rammed in while the plywood pieces were retrackted.

Here is the already hardened body being

stripped down. The top outside former has already been removed, with

help of a saw, as the cylinder turned out slightly concave, which

prevented it from sliding away, so had to cut it free.

Here is the already hardened body being

stripped down. The top outside former has already been removed, with

help of a saw, as the cylinder turned out slightly concave, which

prevented it from sliding away, so had to cut it free.

All

surplus refactory material was jammed (ha ha) into old strowberry jars

to make flints and small pieces of plastic rod were pushed half way

into the material, as show. These left four cavities that server to

vent out an metal that spills on to the furnace floor.

All

surplus refactory material was jammed (ha ha) into old strowberry jars

to make flints and small pieces of plastic rod were pushed half way

into the material, as show. These left four cavities that server to

vent out an metal that spills on to the furnace floor.

Like

I said, rammed it too hard! The bottom plywood former shifted and the

bottom of the furnace body was not orthogonal to the cylinder sides. Oh

well, with a diamond disc and an angle crider it took less than ten

minutes to put this right.

Like

I said, rammed it too hard! The bottom plywood former shifted and the

bottom of the furnace body was not orthogonal to the cylinder sides. Oh

well, with a diamond disc and an angle crider it took less than ten

minutes to put this right.

And

here is the flint, still upside down.

And

here is the flint, still upside down.

The

frame structure for the furnace was welded together from 30 x 30 x 3 mm

angle iron, except for the vertical columns which are 40 x 40 x 5 mm.

The

frame structure for the furnace was welded together from 30 x 30 x 3 mm

angle iron, except for the vertical columns which are 40 x 40 x 5 mm.

The wheels for the moving lifting mechanism were

cut from a 40 mm dia Al block, turned and fitter with ball bearings.

The wheels for the moving lifting mechanism were

cut from a 40 mm dia Al block, turned and fitter with ball bearings.

Here

you see the rather small wheel base

inherent in the Gingery design. How inheret, I'll tell you later.

Here

you see the rather small wheel base

inherent in the Gingery design. How inheret, I'll tell you later.

Here all the main parts of the furnace assemble

meet together for the first time. The lift mechanism is still missing.

Here all the main parts of the furnace assemble

meet together for the first time. The lift mechanism is still missing.

And here the furnace is fully assembled,

ready for action.

And here the furnace is fully assembled,

ready for action.

For the fireworks I decided to try and see if an

oil burner could be utilized. These are readily available as the

companies that sell these are always urging old ladies and gentlemen

that it would be a good time to change that old burner. Usually they

(the burners) are good for

another twenty years, so good second hand burners are easy to obtain.

Here you can see the inlet mounted, ready to accept the burner.

For the fireworks I decided to try and see if an

oil burner could be utilized. These are readily available as the

companies that sell these are always urging old ladies and gentlemen

that it would be a good time to change that old burner. Usually they

(the burners) are good for

another twenty years, so good second hand burners are easy to obtain.

Here you can see the inlet mounted, ready to accept the burner.

And here the complete furnace and burner

assembly before firing up for the first time.

And here the complete furnace and burner

assembly before firing up for the first time.

Revers angle view; no I don't watch hockey. As

you can see the burner is a neat package, the atomizing nozzle, high

voltage ingniter, blower, high pressure oil pump, flame guard

electronics all in one easy to mount piece. Just dip the hoses to a can

of fuel and plug it in and with a press of a button it whoooms!

Revers angle view; no I don't watch hockey. As

you can see the burner is a neat package, the atomizing nozzle, high

voltage ingniter, blower, high pressure oil pump, flame guard

electronics all in one easy to mount piece. Just dip the hoses to a can

of fuel and plug it in and with a press of a button it whoooms!

The nice thing about oil firing is that it is rather safe. I

accidentally un-screwed a plug hole while trying to adjust the burner

which was in full blow. The fuel oil (not sure if that is the correct

english term) bursted out and wetted my hands and the sand below before

I could plug it again. But it never caught fire, as it does not burn

readily!

Finally, here is the result of one hour of oil

heating. Bright read orange, but nowhere near what is required for

casting iron. A dissapointment yes, but

not a big deal, I've still got my MarkIV gas burner and that baby is

hot! I do not think this is conclusive, but atleast with this burner it

was not possible to get anything like the blue hot flame (some 1900 deg

C) that any gass burner easily produces.

Finally, here is the result of one hour of oil

heating. Bright read orange, but nowhere near what is required for

casting iron. A dissapointment yes, but

not a big deal, I've still got my MarkIV gas burner and that baby is

hot! I do not think this is conclusive, but atleast with this burner it

was not possible to get anything like the blue hot flame (some 1900 deg

C) that any gass burner easily produces.

All in all I was not totally happy with this new furnace, so, you guessed it, there have been developments since, but I think I'll leave that to another time and page, so tune in for New Furnace - Part II coming soon to a computer screen near you.

cheers Kusti