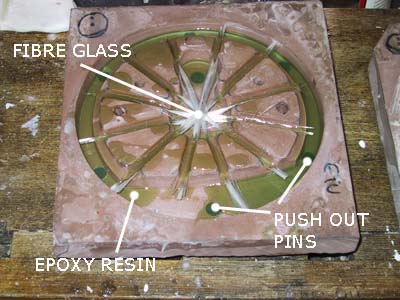

Fiber glass reinforcement was found to be necessary for the spokes to stand the withdrawal of the pattern.

The secret to succesfull withdrawal is a good draught angle, properly waxed mould and PUSH OUT PINS. I used six pins on the rim and one in each center. To push out the pattern the mould was paired with a piece of ply wood. Clamps were used to apply pressure to the pins via the ply wood to force the pattern evenly out.

For finishing the half patterns they were paired together with two bolts so that the allignment of the spokes on the parting plane could be checked. To ensure aligment a file was used!

The pattern for the coupled wheel on the left and the pattern for the driving wheel on the right.